|

| Underwater Drone For Surveillance - Architecture |

INTRODUCTION

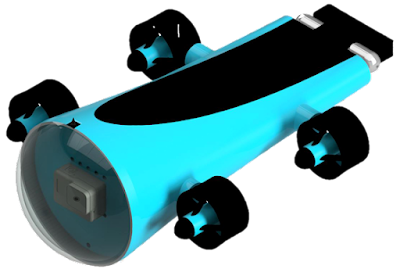

Underwater drone

is a smart device with the use of sensors in lower cost to capture the beauty

of a small pound and gather it from different angle, which human eye is unable

to see.

FEATURES

Drone is

extremely easy to operate due to its internal design and it has multiple

protections which a drone can face under the water in normal conditions. The

drone has the ability to provide a live feed and its smart structure makes it

to operate in 360 degree and also give the life feed to screen.

CAMERA

There is a glass

in front of the drone from where a camera is installed which helps to monitor

the live view under the water without effecting from water. The glass also

helps to cut through the water.

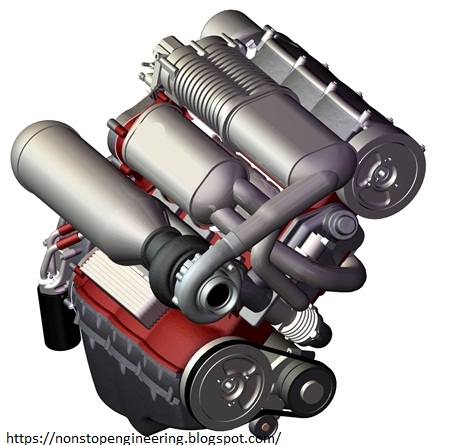

Smart Balancing

The drone has a smart balancing system to itself. The sensor automatically operates the engine

without affecting anything and keeps it at a specific angle in all three

directions.

Object Detection

The drone can

have protection from obstacles. In case of any object in front or beneath

the done, it stops the engine to move in that direction.

Waterproof

The whole

operating system is made of electrical and it is difficult to operate these

appliances underwater. In drones most of the sensors are waterproof but the

rest of the design uses the sealing in the body to avoid water interaction with the internal system.

VISUAL

|

| Underwater Drone For Surveillance - Architecture |

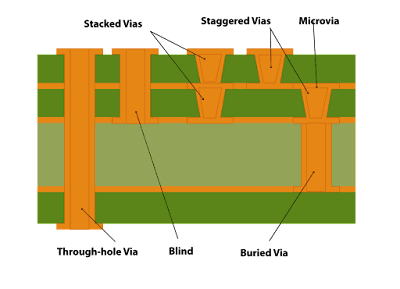

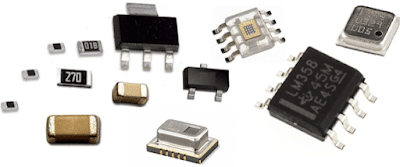

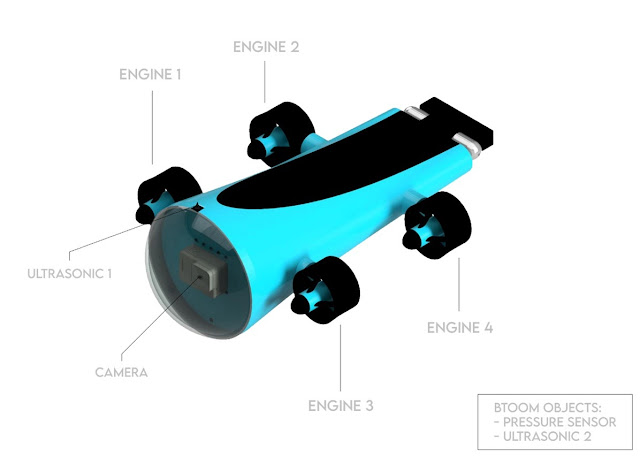

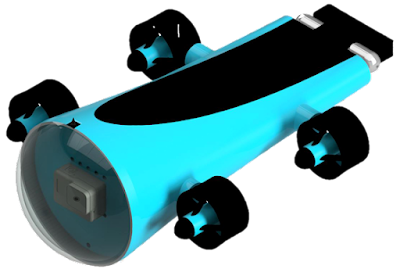

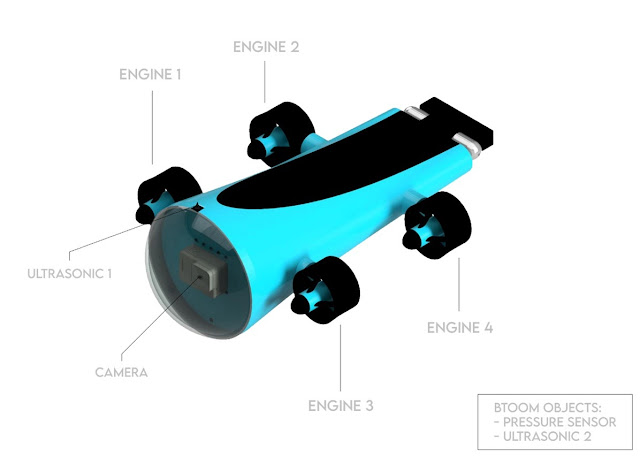

Detail

The features of

drones may be limited but their internal design requires special attention. The

internal structure is a combination of different devices, most of them are

seniors and their spatiality is that they all fit for their role with the

drone. As you can see in the image, we have multiple sensors but some of them

are hidden inside. Let me describe what each device does in the drone.

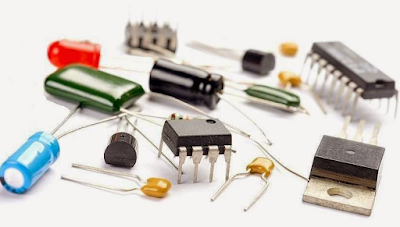

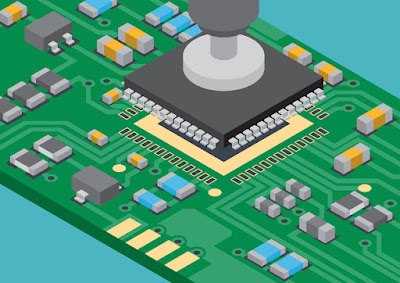

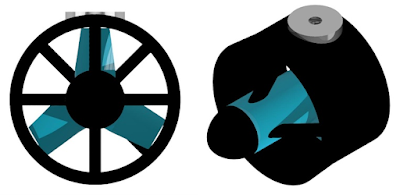

Motors

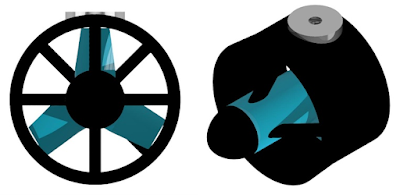

|

| FANS |

In

the drone, there is only one major CPU that controls all the functionality. The

drone processor uses timely loops to control the motors and sensors keep

running in the background to provide the continuous signal. The main drone

functions are its movement. To make the drone moveable, waterproof motors have

been used. The motors are attached to further fans and servo motors. The

combination of servo and other motors helps it to move in all directions without

any issue. The motors use a driver which makes the motors move in both

directions on the basis of the incoming signals.

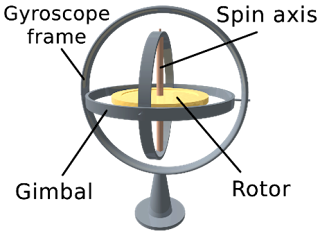

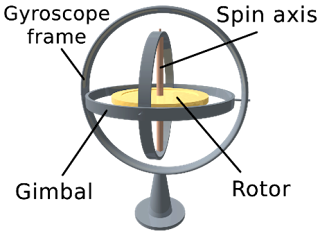

Gyroscope

The motor

movement receives from remote which uses sound waves to send a signal but the

problem here is a little different. When the remote sends the signals to the drone

then its motors start operating as it has been set on different signals. The

problem here is the drone direction can also affect water flow. To avoid

the effect of water on drone movement a gyroscope sensor has been used to

control that. The sensor keeps the drone at a specific angle. Every time the

drone losses its position by water flow, the sensor makes the motors move it

back to its specific point. The basic function of the gyroscope is to tell all of

its angles in all 3d planes. The smart programming helps to automatically operate

the motors in case of a change in angle from a specific point.

|

| Gyroscope |

Camera Feedback

The camera part

is one of the most amazing parts of the drone due to its calculated design. The

camera is hidden behind the glass, from which it takes a full front view. The

glass protects the camera from water and its curvedness makes it cut through

the water. That flow of drones has a much lower effect on drones’ motors. The

camera captures the beautiful movements underwater and sends them to the surface

where it is canalized to the screen which is set on the remote. The live view of the screen can control the drone

but there Is a little bit of latency issue in the whole process. The

millisecond's difference puts the drone in a risky state. This problem is solved

by some other sensors.

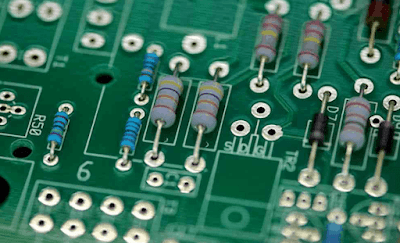

Ultrasonic Sensors

There are two

waterproof ultrasonic sensors attached to the drone. The one is on the head of

the drone which checks the obstacle in the front direction and the other one is

attached beneath the drone. It checks the obstacle under the drone. Both

sensors help to avoid obstacles in case a user is unable to view on the screen.

Both of these sensors are waterproof and specially designed to operate

underwater. Besides these sensors, there are some others, especially in the drone.

There are other two sensors that help to decide the underwater environment.

|

| Sensor |

Temperature Sensor

The temperature

sensor helps to avoid the high and low temperature issue. The temperature

sensor it helpful when an animal is near to the drone. It can calculate the

water temperature. The temperature sensor only helpful in close interaction of

an animal but the other sensor known as pressure sensor solve the other issue.

Pressure Sensor

The pressure

sensor helps to calculate the pressure of the water. In case of water pressure

changes then it can be received by the pressure sensor. The pressure sensor has

a higher chance of measuring animal presence from a larger distance than the

temperature sensor. So, in that case, a drone camera can be moved to the other

direction to view the animal. That is really helpful to capture the movement

and can also be used to save the drone from larger size animals like whales. The

pressure sensor not only works as a pressure sensor. It also works as a

temperature sensor too. The usage of two temperature sensors helps to minimize

the error by getting two readings.

Lights

There are two

led lights are attached to the drone at the front. These lights help to clear

the darkness coming in the camera. The lights give the proper view to the

camera and help to capture the best visuals. The led button is present on the

remote. So, in case to turn off the led the button will be helpful. The led and

drone will be fully controlled through

Monitoring

The monitor part

is very helpful for drone movement but it has some specific limitations. In

which the main one is the time delay between camera and screen due to the low

latency rate. So, to operate the drone always keep in mind that it has sensor

values that show on the top of the screen. Always keep an eye on the top of the

screen, that is really helpful.

Drone Body

The

body of the drone is fully optimized according to the water flow and sensor

requirements. The body helps to operate the engine in a smart way. Especially it

helps to make a path in the water and also helps in standing on the water in case

of water. There will be water resistance on the drone but the design of the

body minimizes it in many ways.

WARNINGS

|

|

Don’t

open the drone, unless you have knowledge about its internal structure. It

has been sealed to protect itself from water.

|

|

Don’t

place the drone in hot water the other camera and ultrasonic sensors could be

affected by high temperature

|

|

Keep an eye on the sensor values to operate efficiently.

|

Note: The Drone image and 3d file were taken over the internet just to represent the project.

![Window 10 pastes random hashed string [Solved] Window 10 pastes random hashed string [Solved]](https://1.bp.blogspot.com/-NLMMwdA07UE/YY_v0twlZuI/AAAAAAAAJwE/qEtHnUIiQeQoOF7CeMxz24SyvBVznfWTQCLcBGAsYHQ/w640-h428/computer-virus.jpg)

![Window 10 pastes random hashed string [Solved] Window 10 pastes random hashed string [Solved]](https://1.bp.blogspot.com/-auD7v3sy8EE/YY_tEfuTfmI/AAAAAAAAJv0/Qnkjzln70GgjwV3BFo9PqKM92oXMLJ-sgCLcBGAsYHQ/w640-h360/svhost.jpg)

![Window 10 pastes random hashed string [Solved] Window 10 pastes random hashed string [Solved]](https://1.bp.blogspot.com/-AFWtsWgmADg/YY_t8tX3KCI/AAAAAAAAJv8/oNadHBJLUgESk3Li2XYKqtntSBGQw3gxgCLcBGAsYHQ/w640-h360/logui.jpg)