Two-stroke combustion cycle:

- A two-stroke engine produces twice as many power strokes per revolution as its four-stroke equivalent. This advantage leads to smaller displacement engines for similar performance, and lower in-cylinder pressure to lower emissions compared to four-stroke conventional engines.

- In the past, these advantages were balanced by some well-documented shortcomings of two-stroke engines, which limited their scope of use. High hydrocarbon emissions (due to carburetion and over-scavenging) and excessive oil consumption (due to oil-fuel mixing in spark-ignition engines and port oil ejection in compression ignition, direct fuel injection engines) are difficult issues to tackle in these type of engines.

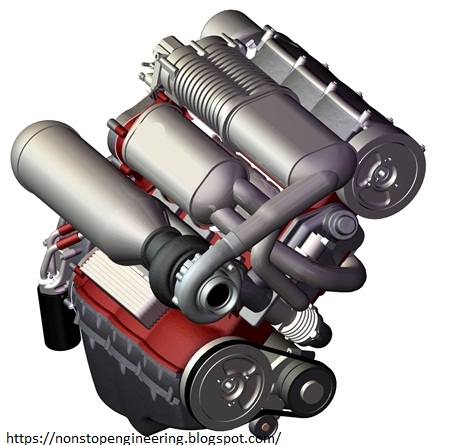

- The engineers and scientists started Achates Power in 2004 with the audacious idea that innovation and modern technology could transform the proven and record-setting two-stroke opposed-piston engines of the past into the clean and efficient engines of the future.

- This advantage reduces the fuel used per cycle, resulting in shorter and leaner combustion for optimally phased energy release – all enhancing engine efficiency.

- Achates Power’s extensive prototyping capabilities and state-of-the-art test facilities are instrumental to confirm at every step the validity of our analytical approach and results.

- The proprietary cylinder and piston designs achieve unprecedented improvements in combustion efficiency and oil consumption to meet the most stringent emissions regulation. In conjunction with the thermal efficiency advantage inherent to opposed-piston engines, our designs realize significant reductions in fuel consumption over conventional four-stroke compression ignition engines. Based on its unique technology, Achates Power is creating clean, more fuel efficient and lower cost engines for the 21st Century.

Compression ignition engines achieve superior thermal efficiency by the virtue of their higher expansion ratio, inherent fuel-lean combustion and reduced pumping losses.

Although the very first compression ignition engine, designed by Rudolph Diesel in 1894, ran on pure peanut oil, today’s compression ignition engines rely on diesel fuel, thanks to its unique combination of qualities:

- Energy dense, takes less volume and weight in vehicles

- Clean, with the recent introduction of ultra-low sulphur diesel fuel

- Widely available, throughout the world

- Most cost-effective, in the current economic conditions

- In the US, 25% of the fuel used by cars, trucks and buses is diesel fuel

- In China and India, diesel represents 2/3 of the fuel used for road transportation

- One out of two passenger cars registered in Europe is compression ignition/diesel powered

And when the cost to use fossil fuels becomes too high, improved compression ignition engines will be ready for the renewable fuels of tomorrow. Already, in 2008, the U.S. produced 691 million gallons of biodiesel(3). Second generation renewable compression ignition fuels from soybeans, biomass, algae and other sources promise that more efficient compression ignition engines are key to a cleaner and safer future for transportation.

Post a Comment